Perfect Your Plastic Components:

Technology by Manufacturing Experts

for Manufacturing Excellence

At sensXPERT, we offer an advanced process control solution that goes beyond conventional process monitoring, visualizing material behavior in real time to guarantee the highest performance and quality in plastics manufacturing.

Are You Looking for Answers to These Questions?

How can we decrease economic losses, become independent of material and process deviations, and still utilize our production’s full potential?

How can we save energy, reduce waste, produce components of the highest quality, yet still meet the requirements for improved sustainability?

We have the answers!

Reach Your Manufacturing Targets with sensXPERT

Our innovative dielectrics-based technology seamlessly adapts to a wide range of production processes, ensuring quality and efficiency across diverse industries and materials. Explore how we detect and resolve deviations in real-time to optimize your production outcomes.

Composites

- Aviation & Defense

- Automotive

- and more…

Thermosets

- E-mobility

- Electrical Encapsulation

- and more…

Elastomers

- Pumps

- and more…

Thermoplastics, Recyclates, PCR

- Automotive

- and more…

Achievable Results with sensXPERT

1… 2… 3… go!

Material composition – detected in seconds

30% Cycle time reduction potential

Boost your production output

and achieve a quicker turnaround.

Cut existing scrap rates by up to 50%

Minimize waste and maximize profits

with fewer rejects.

Investment amortized

in less than 3 months

Leverage Material Behavior and Machine Insights in Real-Time

Today’s material processing is dynamic

sensXPERT’s toolbox technology tackles the complexities of process optimization head-on, accurately identifies material mixes, and swiftly detects anomalies as they arise. Its user-friendly hardware, powered by cutting-edge machine learning and AI, ensures cost-effective, high-quality production while advancing sustainability in manufacturing.

Your Return of Investment

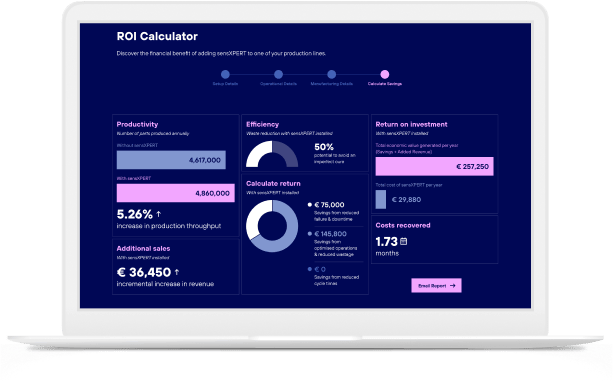

ROI Calculator

Calculate the real value of sensXPERT for your OEE

Considering sensXPERT for your business? Use our powerful ROI calculator and see how much of a return this could make for your business.

Launch ROI calculator